24/7 Emergency Hotline: 905-501-0802

Customer Care Hotline: 1 (888) 256-7359

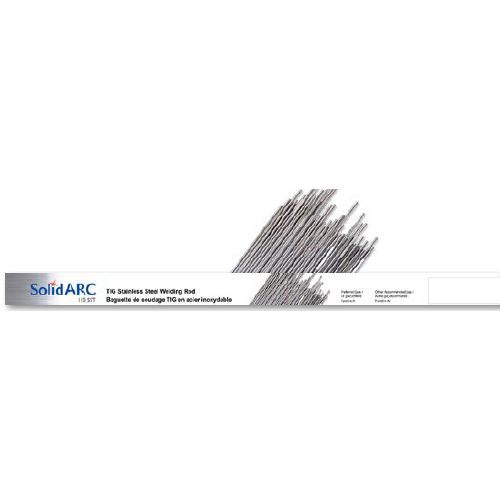

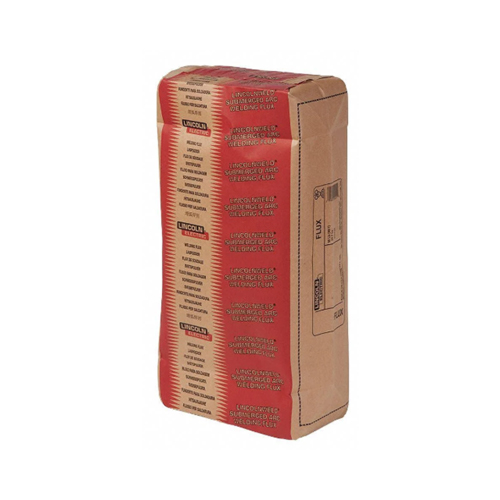

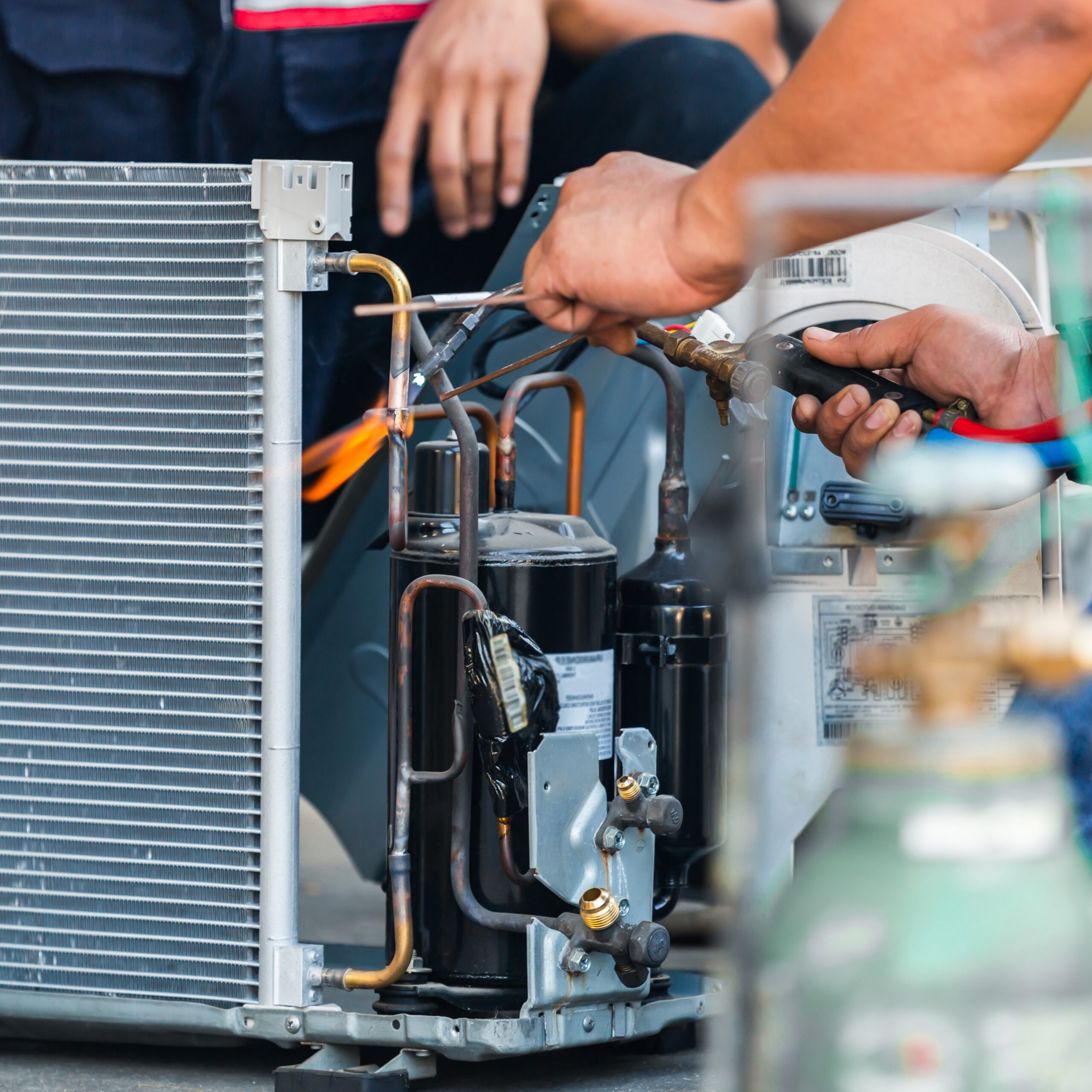

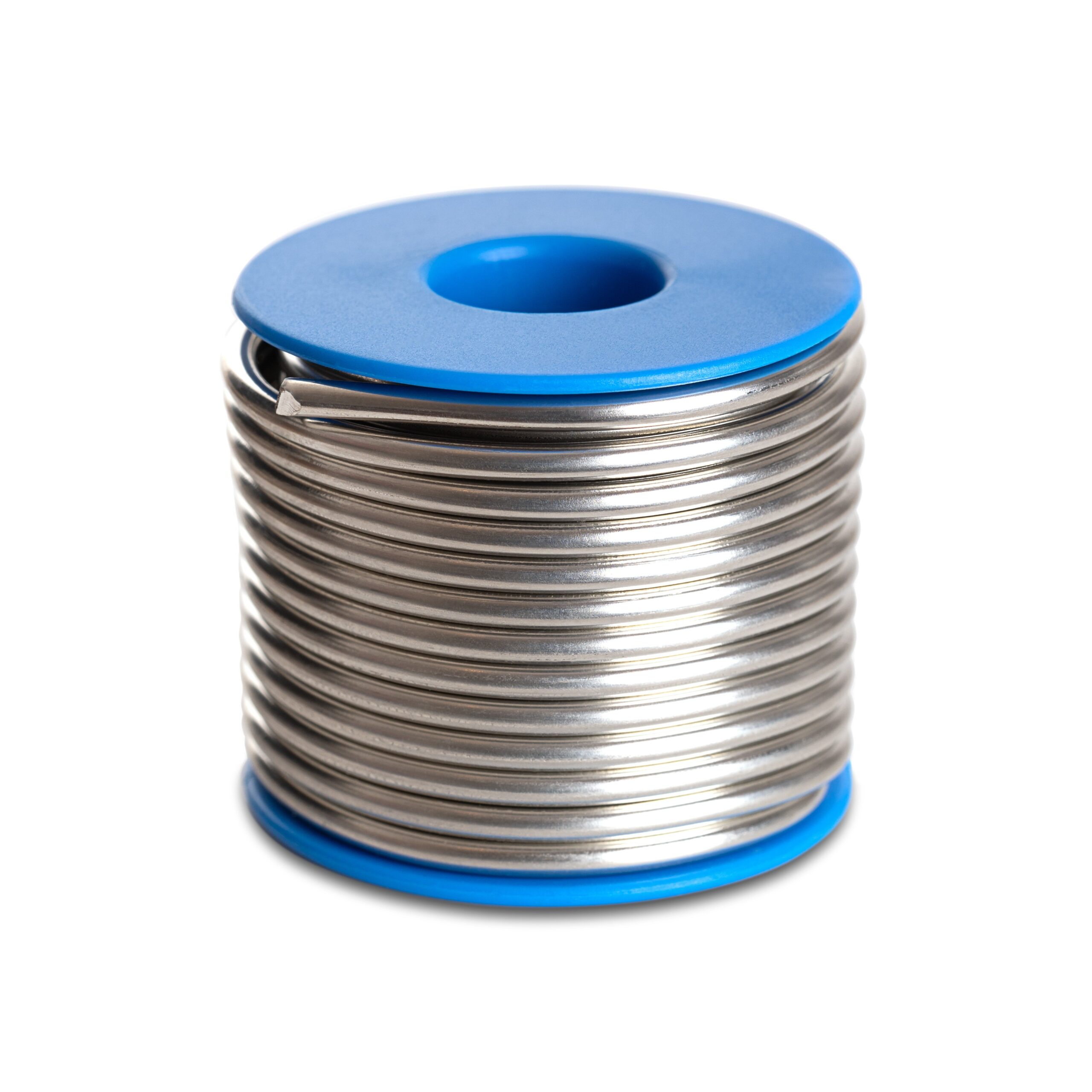

SolidARC welding consumables deliver consistent performance, smooth arc stability, and superior weld quality across MIG, TIG, and flux-cored applications. Engineered for mild steel, stainless steel, and aluminum, these wires and filler metals meet CWB certification standards and undergo rigorous testing to ensure precision and reliability. With strong supply availability, competitive pricing, and full traceability, SolidARC provides welders and fabricators with the high-quality materials needed for efficient and durable welds.

Browse our full line of SolidARC products on Messer WebShop

Stay In The Loop. Subscribe to our newsletter for news & promotions.

Messer is the largest privately held industrial gas business in the world and a leading industrial and medical gas company in North America, South America, Asia and Europe. Messer offers more than 125 years of expertise in industrial, medical, specialty and electronics gases. The company delivers quality gases, related services and technology via an extensive production and distribution network. Health and safety, sustainability practices and environmental protection are core Messer values that are embedded in the company’s daily operations. Messer Americas sales account approximately for 52% of Messer worldwide sales of over $4.8 billion USD.

For more information, visit: www.messeramericas.com

© 2025 Messer Canada Inc.

Subscribe to our newsletter to receive the latest Messer news, product updates, and exclusive promotions straight to your inbox.